Efficiency: Updating capabilities, improving

capacity, reducing costs

If I were to tell you that there was a way to reduce

costs, electrical efficiency capabilities, and

enhance electrical capacity through a product

you needed – would you buy it? Of course you

would! Smaller, faster, cheaper – the name of

today's engineering game.

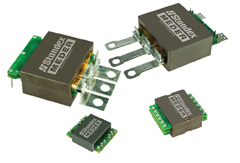

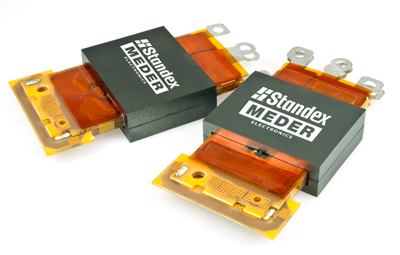

Planar transformers are steadily replacing the

need for traditional wire-wound transformers in

many industries. Electric vehicles, solar inverters,

wind power, telecommunications, mil-aero,

aviation, healthcare, industrial applications,

tools, LED lighting, induction heating/charging,

appliances, electronics (TV's, radios, etc.), and

many others. Core materials, their shapes, and

manufacturing techniques are all developments

Standex-Meder have been in tune with to deliver

to various requirements.

With the ever increasing need to be faster,

perform with greater accuracy, improve time to

market, and reduce costs – planar transformers

replace the traditional wire wound transformers

with a solution that makes perfect sense for a

successful blueprint.

Why Standex-Meder Planar Transformers?

- Repeatability, high-performance and reliability

- Multiple winding options and topologies

- Low profile height and lightweight

- Low leakage inductance

- Space savings and capacity improvement (retro/custom fits)

- High efficiency (resistance, flux density)

- Customized terminations

- Volumetric efficiency (small size)

- High voltage isolation transformers

- Low turns count improves Cu loss

- Large core surface promotes heat transfer

- PCB construction yields lowest Cu loss

- AC resistance and proximity Cu loss minimized

- Opportunity to embed planar into PCB

module (integrated magnetics)

- Optimized core cross section lowers core

loss

For a switched-mode power supply (SMPS), our

planar transformers act as the main component

and the smart choice for converting power and

doing the transformation of the voltage effectively.

Smaller volume planars can handle the same

amount of work as larger wire-wound transformers.

General guide on how to design and

use planar transformers

- Choose optimum core cross section

- Choose optimum core window height

- Iterate turns vs. duty cycle

- Core loss

- Cu loss

- ate thermal methods

- Estimate temperature rise

- Tradeoff cost vs. number of layers

- Mechanical design fit envelope pad layout

- Fit within core window height

- Size sufficient for power loss and thermal

solution

Example where planar transformers

reside

- Distributed isolated power

- Battery charging and operation (12V, 24V, 48V, and 1-10KW)

- Isolated inverters (to 50KW)

- Renewable energy sources (wind and photovoltaic)

- AC-DC resonant designs

Industry applications

Automotive, Aviation, Military, Medical, Telecommunications,

Electronics, Industrial, Power,

Appliances, Transportation, Alternative/Solar

Energy, Lighting/LED, and others where planar

transformers provide efficient power distribution

and high frequency switching.